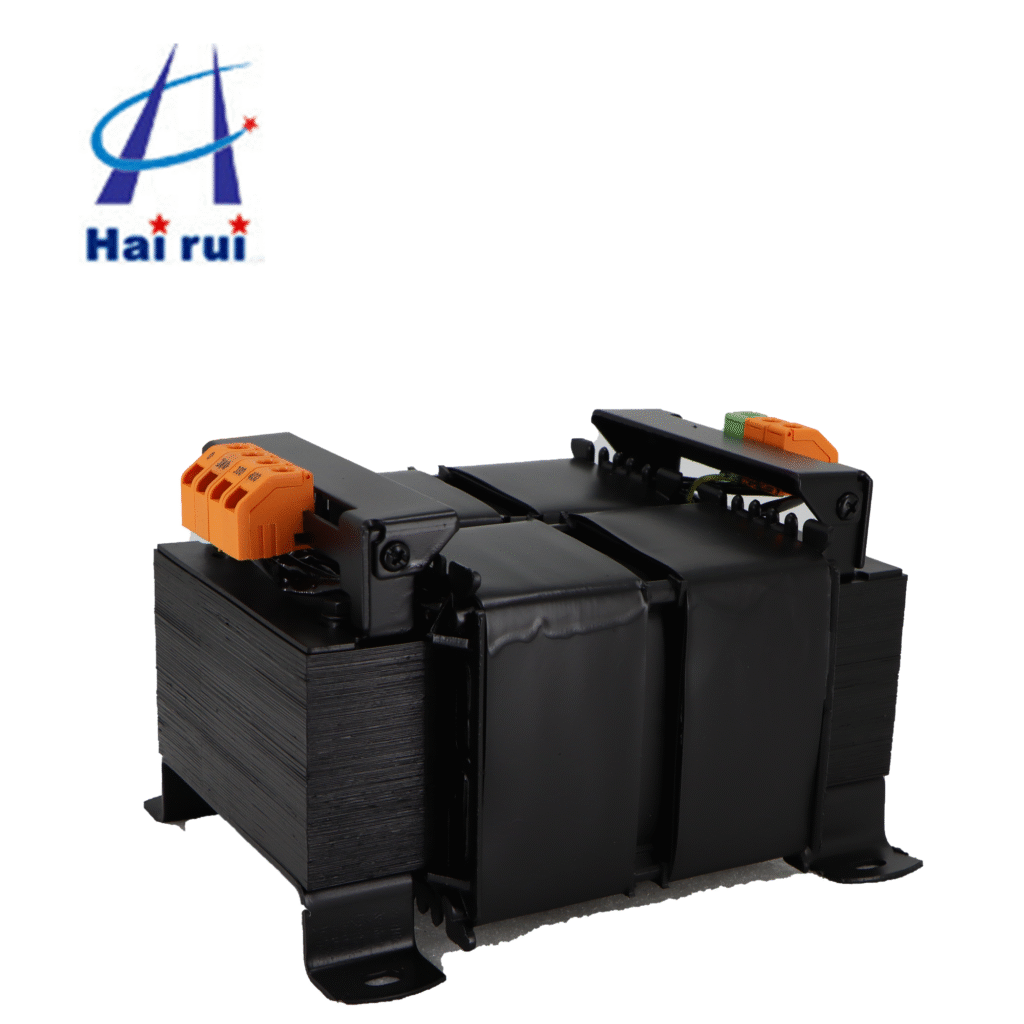

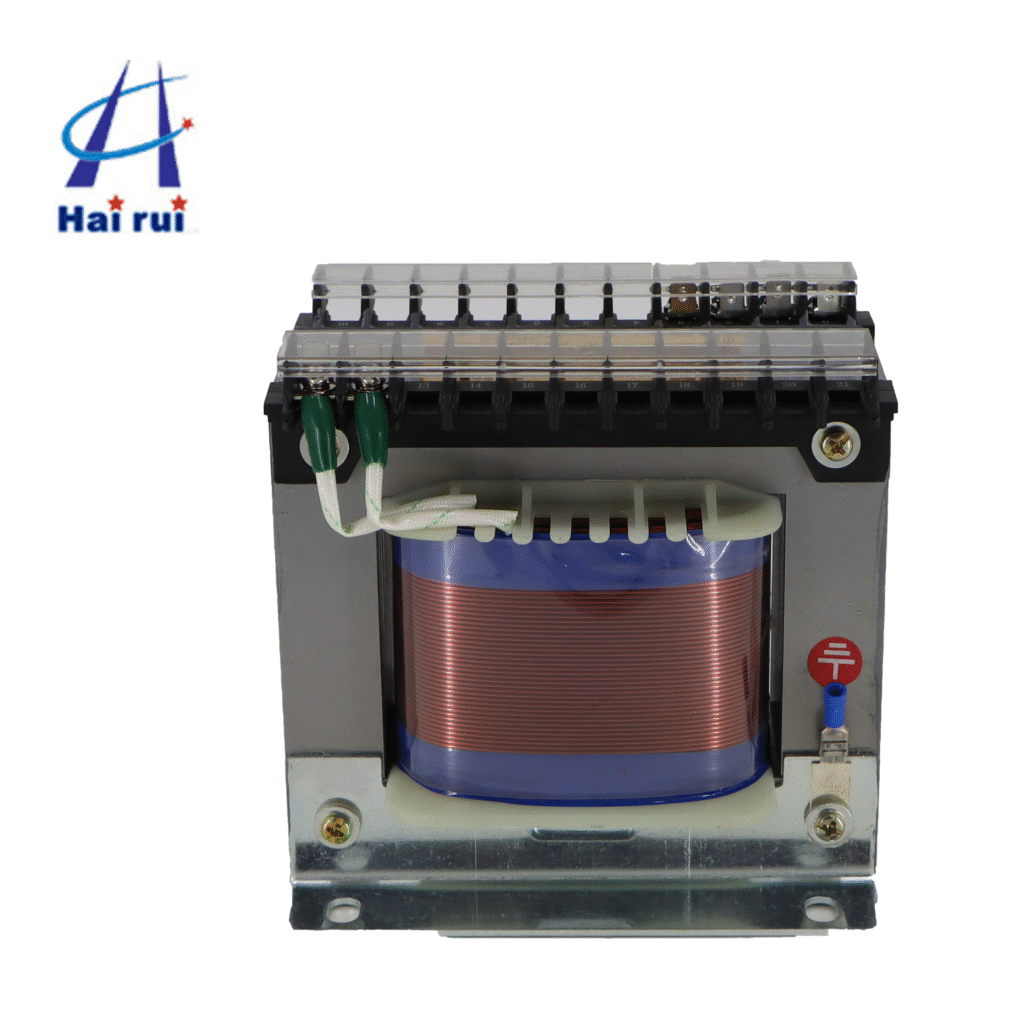

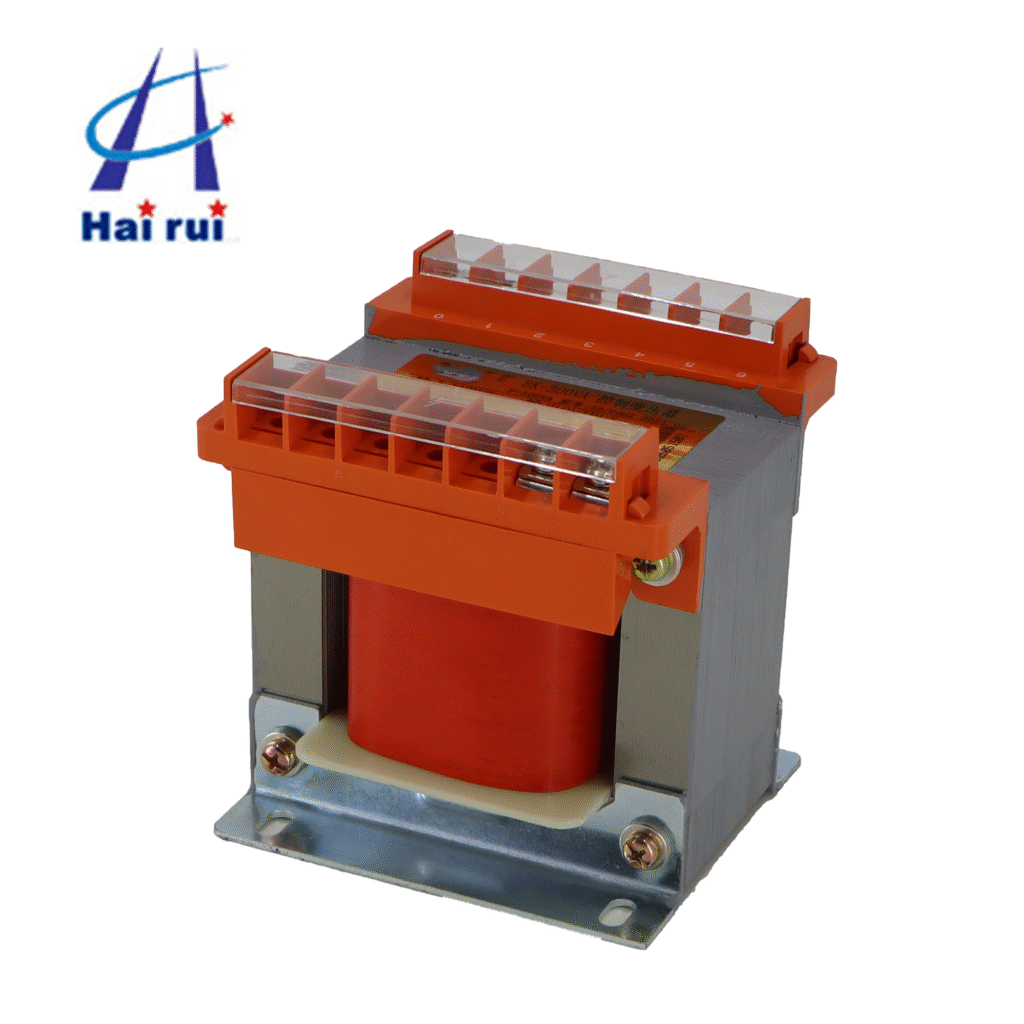

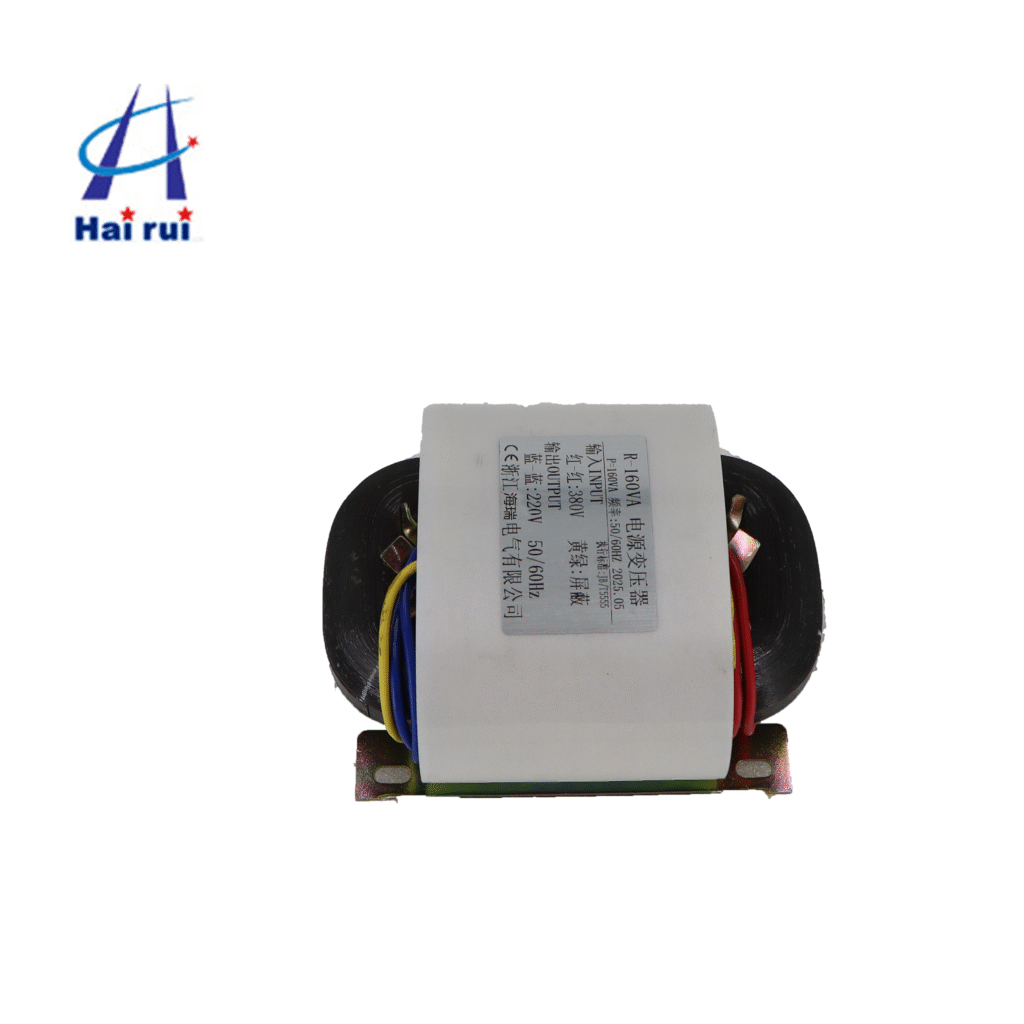

An oil-fired delta transformer is a type of oil cooled distribution transformer that adopts a delta connection winding method. The delta configuration allows balanced power distribution, while the oil insulation enhances cooling and protects the windings against overheating and electrical faults.

With its robust oil-filled design, this delta wound oil transformer ensures safety, energy efficiency, and long service life even under heavy operating conditions. It is widely applied in factories, substations, renewable energy systems, and commercial complexes.

Core Features

-

Delta winding connection – provides balanced load sharing and reduced harmonics.

-

Oil immersion cooling – ensures stable thermal performance.

-

High dielectric strength – oil insulation minimizes risks of flashovers.

-

Customizable voltage ratings – suitable for low and medium voltage distribution.

-

Heavy-duty construction – designed for demanding industrial applications.

-

Overload resistance – maintains performance under varying load conditions.

Product Advantages

-

Enhanced efficiency – supports long-term, reliable power transmission.

-

Cost-effective – lower maintenance needs compared to dry-type alternatives.

-

High durability – resistant to moisture, dust, and environmental challenges.

-

Thermal stability – oil cooling improves transformer life expectancy.

-

Scalability – available in multiple capacities for flexible system integration.

-

Trusted safety – reduced risk of electrical faults in delta connected systems.

Applications

The oil fired delta transformer is versatile across multiple industries:

-

Utility distribution networks – stable operation for local grids.

-

Manufacturing plants – heavy machinery and production lines.

-

Renewable energy stations – wind farms, solar power plants.

-

Commercial infrastructure – malls, hospitals, and office towers.

-

Mining & heavy industry – demanding load environments.

-

Transportation hubs – railway networks, airports, seaports.

Installation & Maintenance

Installation steps:

-

Place the transformer on a stable, vibration-free foundation.

-

Ensure proper oil level and sealing before energizing.

-

Connect grounding system and delta windings securely.

-

Test insulation resistance before loading.

Maintenance recommendations:

-

Monitor oil temperature and quality periodically.

-

Conduct oil sampling to check dielectric strength.

-

Inspect bushings, gaskets, and terminals for leakage.

-

Schedule load testing and thermal inspections annually.

How to Choose the Right Oil-fired Delta Transformer

When selecting a delta connected oil-filled transformer, evaluate:

-

Rated power capacity – based on load demand.

-

Operating environment – indoor vs. outdoor conditions.

-

Voltage class & frequency – compatibility with grid requirements.

-

Cooling method – natural oil cooling (ONAN) or forced cooling (ONAF).

-

Efficiency class – select energy-efficient models to reduce losses.

-

Supplier reliability – choose certified transformer manufacturers with proven expertise.

FAQ

What is the advantage of delta connection in transformers?

Delta connection allows balanced load sharing, reduces harmonics, and ensures uninterrupted operation even if one winding is lost.

Why use oil instead of air cooling?

Oil immersion improves insulation, reduces hotspots, and extends transformer service life.

Can oil-filled delta transformers be used outdoors?

Yes, they are designed with sealed tanks to withstand harsh outdoor conditions.

How often should transformer oil be tested?

It’s recommended to perform oil quality tests every 12–24 months depending on load conditions.

Are oil-fired delta transformers eco-friendly?

Yes, modern insulating oils are biodegradable and designed with safety standards for environmental compliance.

Request a Quote Now

Our team will get back to you within 24 hours.