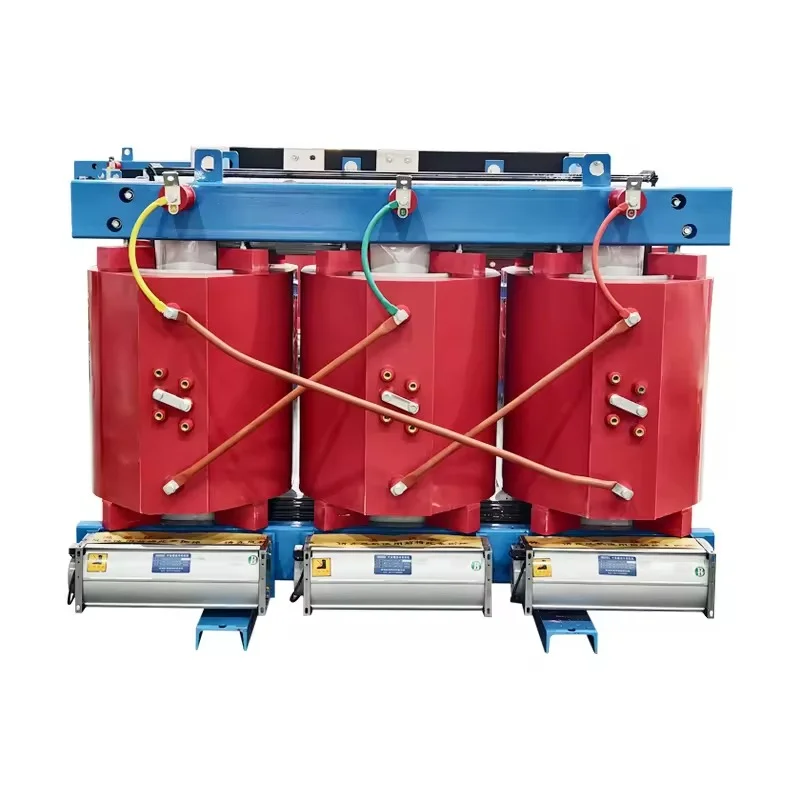

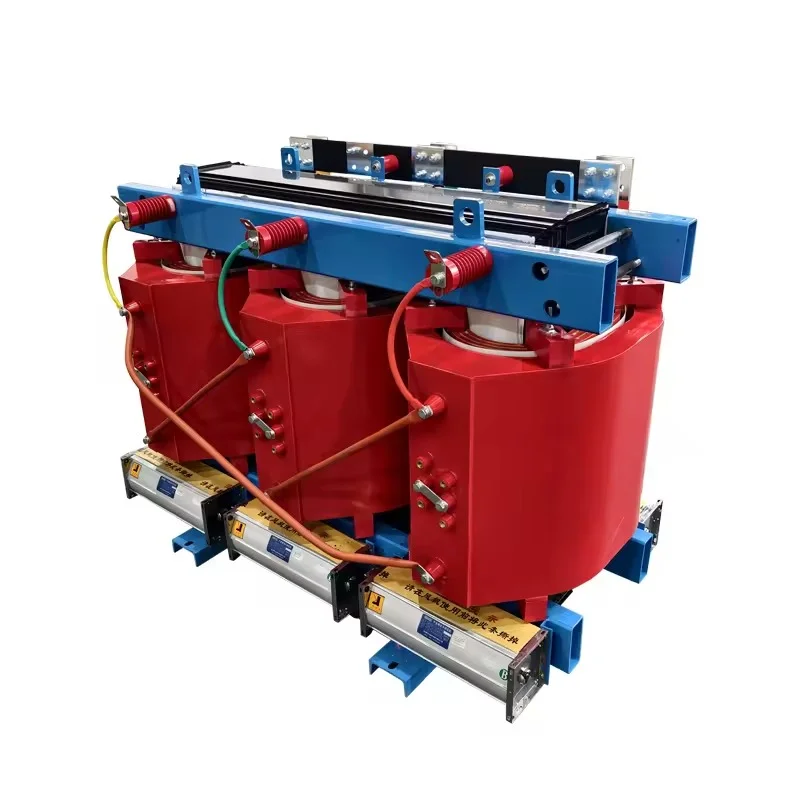

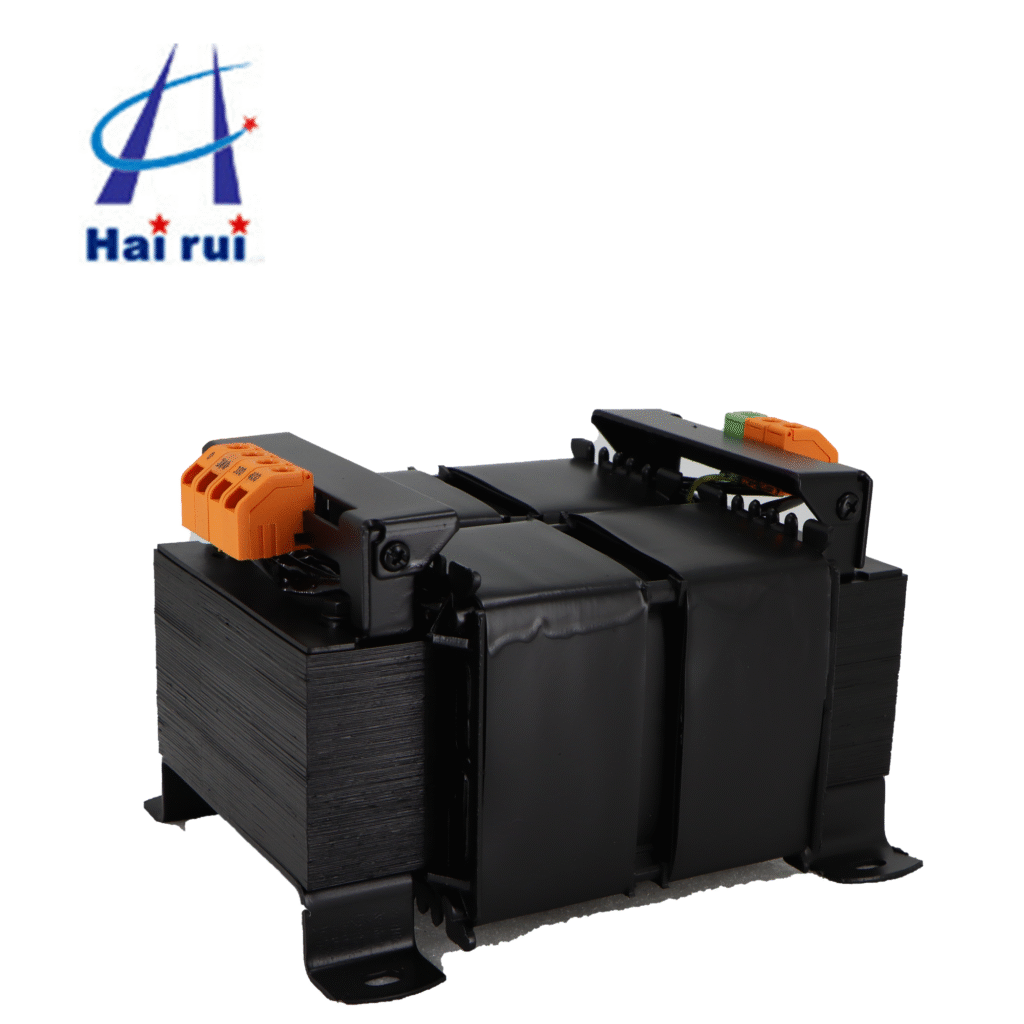

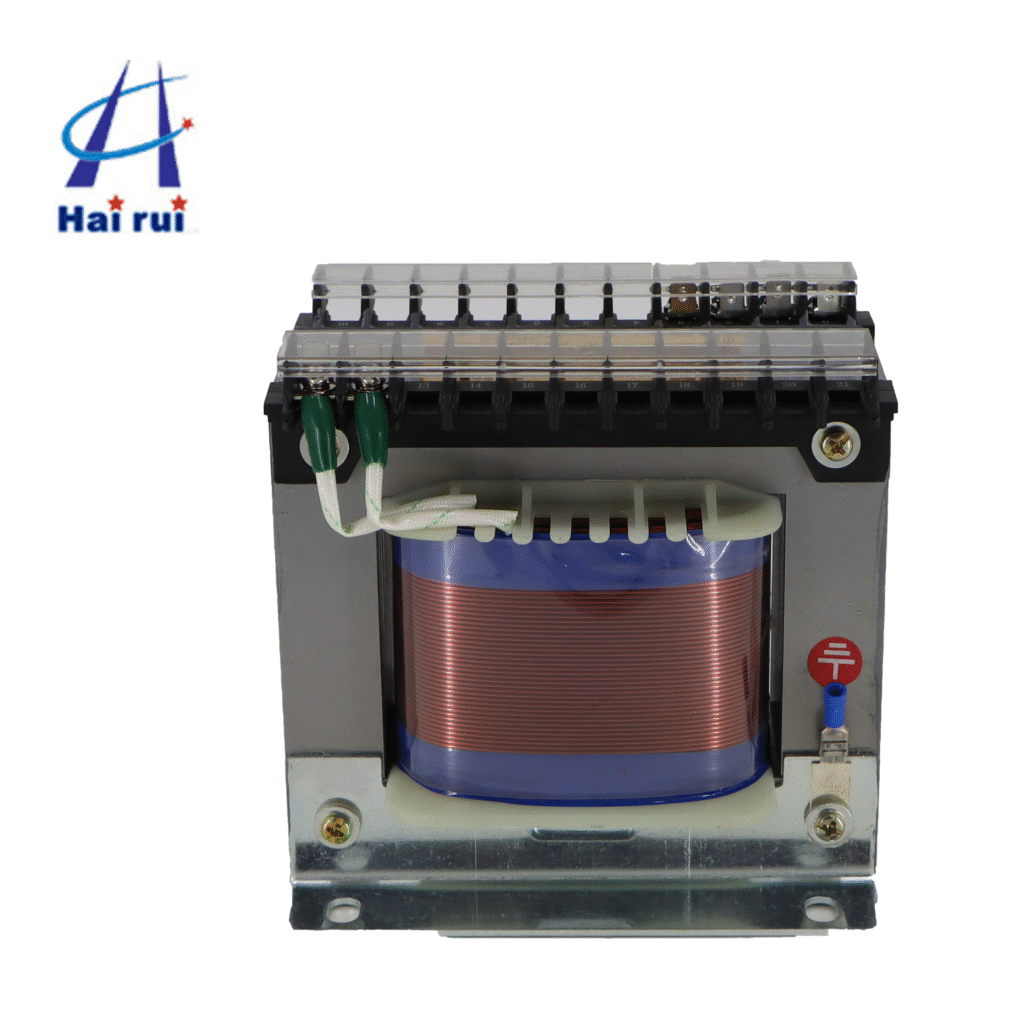

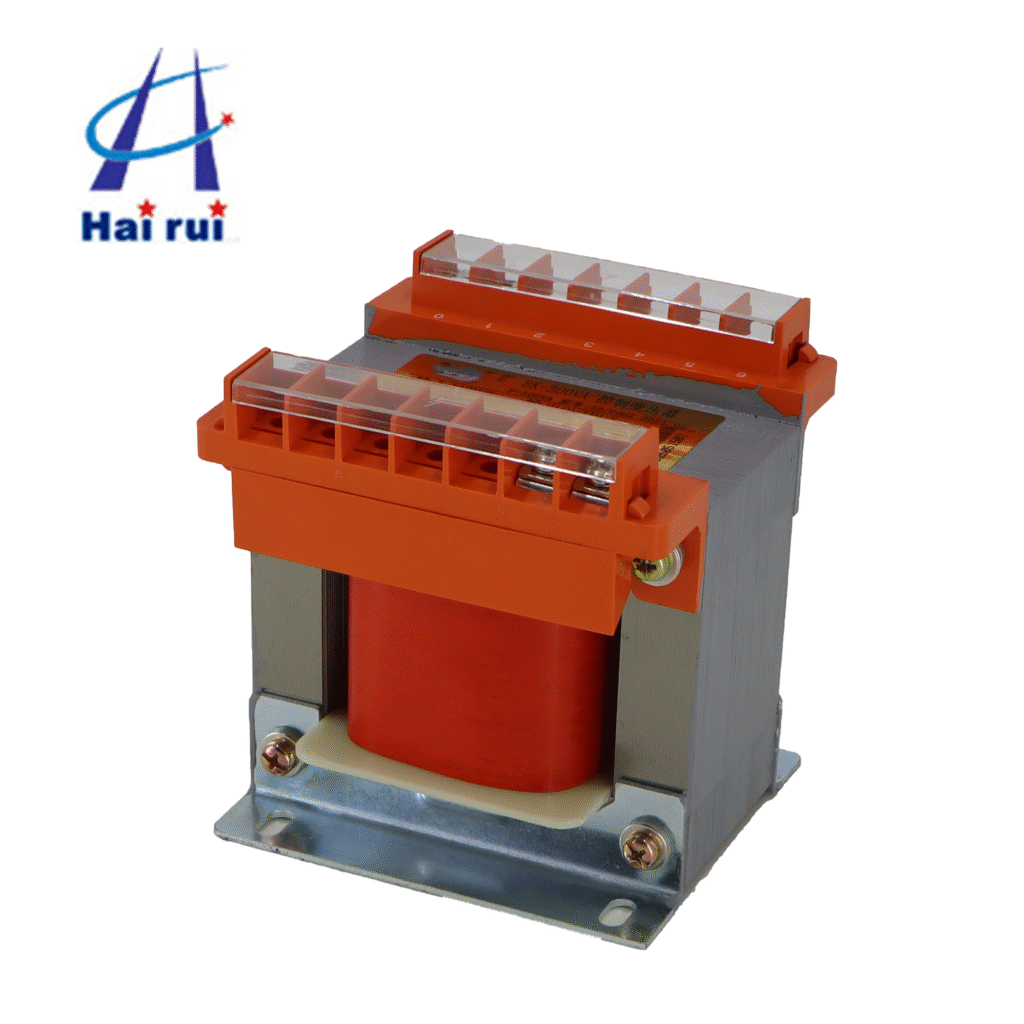

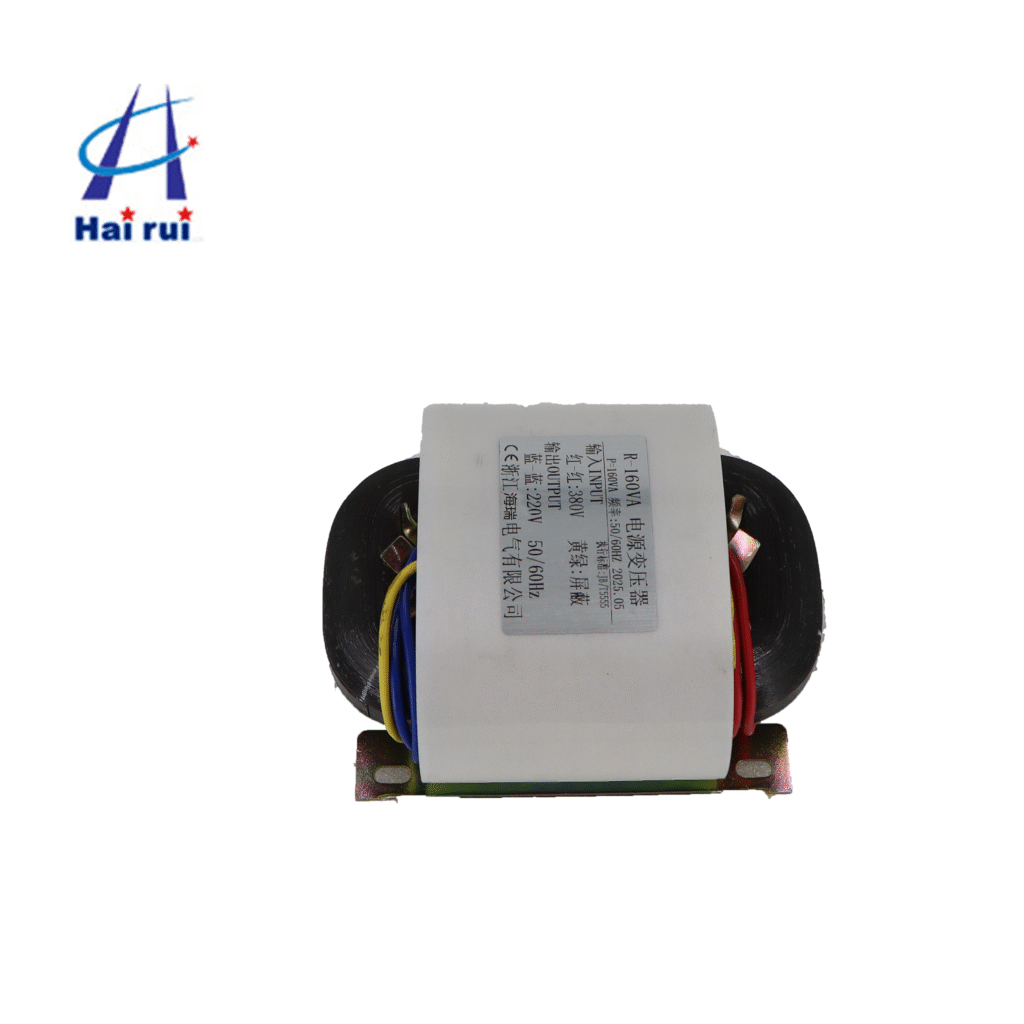

Unlike traditional oil-filled units, a dry-type transformer operates without liquid insulation, making it safer, environmentally friendly, and easier to maintain. This makes it the preferred solution for projects where fire resistance, moisture protection, and reduced maintenance are critical. Our advanced dry type distribution transformers come in various power ratings and configurations, ensuring compatibility with diverse applications across multiple industries.

Key Features

- High efficiency with minimal energy loss during voltage conversion.

- Eco-friendly design with no risk of oil leakage or environmental contamination.

- Superior insulation system using epoxy or cast resin for maximum protection.

- Quiet operation ideal for office buildings, hospitals, and commercial complexes.

- Compact structure designed for easy installation in restricted spaces.

- Enhanced fire safety thanks to flame-retardant materials and robust thermal stability.

Advantages of Choosing Our Dry-type Transformers

Partnering with a professional dry-type transformer supplier ensures long-term reliability and reduced downtime. Our products are:

- Low-maintenance – no oil checks, filtration, or leakage management required.

- Durable – resistant to humidity, dust, and corrosive environments.

- Safe – designed with overload protection and built-in cooling systems.

- Flexible – available in multiple voltage levels for medium- and low-voltage applications.

- Certified quality – all units comply with IEC, CE, and ISO standards.

| Rated Capacity (kVA) |

L | W | H | D | A | |

| 50 | 1180 | 750 | 1010 | 820 | 820 | |

| 100 | 1210 | 780 | 1060 | 820 | 820 | |

| 160 | 1260 | 800 | 1100 | 820 | 820 | |

| 200 | 1310 | 840 | 1100 | 820 | 820 | |

| 250 | 1370 | 880 | 1170 | 820 | 820 | |

| 315 | 1420 | 880 | 1230 | 820 | 820 | |

| 400 | 1450 | 910 | 1280 | 820 | 820 | |

| 500 | 1470 | 910 | 1380 | 820 | 820 | |

| 630 | 1545 | 950 | 1495 | 820 | 820 | |

| 800 | 1600 | 980 | 1560 | 820 | 820 | |

| 1000 | 1620 | 1050 | 1560 | 950 | 820 | |

| 1250 | 1760 | 1050 | 1560 | 950 | 820 | |

| 1600 | 1800 | 1070 | 1660 | 950 | 820 | |

| 2000 | 1840 | 1100 | 1710 | 1070 | 950 | |

| 2500 | 1900 | 1160 | 1880 | 1070 | 1070 | |

| 3150 | 1980 | 1240 | 1920 | 1070 | 1070 | |

| Note:As product dimensions may be continuously improved,the outline dimensions provided in this sample are for reference only.For special dimensions,we can design and manufacture according to user requirements.Please contact our company in a timely manner! The voltage can be interchanged between 20kV and 10kV,and the technical parameters comply with the standards of 20kV class. |

||||||

Applications

Our dry-type transformer equipment is widely used in:

- Commercial buildings – malls, office towers, airports, and hospitals.

- Industrial facilities – factories, manufacturing plants, and processing centers.

- Renewable energy projects – wind farms and solar plants requiring efficient step-up and step-down transformers.

- Infrastructure projects – subways, railway stations, and power distribution networks.

- Marine & offshore applications – environments where safety and space-saving solutions are critical.

Installation & Maintenance

Installing a dry type transformer is straightforward. Position the unit on a level foundation, ensure proper ventilation, and connect according to the wiring diagram provided. Since these transformers are virtually maintenance-free, routine checks focus on:

- Inspecting ventilation and cooling pathways.

- Cleaning accumulated dust on windings and enclosures.

- Checking electrical connections for tightness.

- Monitoring load capacity and operating temperature.

| Rated high voltage:20kV Rated low voltage:0.4kV |

Connection Group:Dyn11 or Yyn0 | |||||||||

| Insulation Level:L1125AC50/L10AC3 | ||||||||||

| High voltage tapping range:±5%or 2×2.5% | ||||||||||

| Rated Capacity (KVA) |

Voltage Combination(kV) | Connection Group Designation |

No-load Loss(kW) |

Load Losses(kW)under Different Insulation Temperature Resistance Grades |

No-load Current % |

Short-circuit Impedance UK(%) |

||||

| High Voltage |

High voltage tapping range |

Low Voltage |

B(100℃) | F(120℃) | H(145℃) | |||||

| 50 | 20 22 24 |

±5 ±2×2.5 |

0.4 | Dyn11 Yyn0 |

0.380 | 1.230 | 1.300 | 1.390 | 2.4 | 6.0 |

| 100 | 0.600 | 1.980 | 2.100 | 2.250 | 1.8 | |||||

| 160 | 0.750 | 2.470 | 2.600 | 2.800 | 1.8 | |||||

| 200 | 0.820 | 2.950 | 3.100 | 3.310 | 1.6 | |||||

| 250 | 0.940 | 3.440 | 3.500 | 3.910 | 1.5 | |||||

| 315 | 1.080 | 4.100 | 4.300 | 4.600 | 1.4 | |||||

| 400 | 1.280 | 4.900 | 5.100 | 5.460 | 1.4 | |||||

| 500 | 1.500 | 5.800 | 6.100 | 6.500 | 1.2 | |||||

| 630 | 1.700 | 6.880 | 7.200 | 7.750 | 1.2 | |||||

| 800 | 1.950 | 8.230 | 8.700 | 9.300 | 1.2 | |||||

| 1000 | 2.300 | 9.720 | 10.300 | 11.000 | 1.0 | |||||

| 1250 | 2.650 | 11.500 | 12.150 | 13.000 | 1.0 | |||||

| 1600 | 3.100 | 13.780 | 14.600 | 15.650 | 1.0 | |||||

| 2000 | 3.600 | 16.300 | 17.250 | 18.500 | 0.8 | |||||

| 2500 | 4.300 | 19.350 | 20.400 | 21.800 | 0.8 | |||||

| 2000 | 3.600 | 17.800 | 18.800 | 20.000 | 0.8 | 8.0 | ||||

| 2500 | 4.300 | 21.300 | 22.400 | 23.900 | 0.8 | |||||

| Note:The load losses listed in the table are values at the reference temperature in parentheses(as specified in GB1094.11). | ||||||||||

How to Choose the Right Dry-type Transformer

When selecting a dry-type transformer manufacturer, consider the following:

- Power capacity required for your project.

- Primary and secondary voltage levels to match your electrical system.

- Type of insulation (cast resin vs. vacuum pressure impregnated).

- Installation environment – indoor, outdoor, or high-humidity conditions.

- Compliance with safety and energy-efficiency standards.

Working with an experienced dry-type transformer equipment supplier ensures not only the right selection but also technical support and after-sales service.

FAQ

What is the lifespan of a dry-type transformer?

Typically 20–30 years with proper installation and minimal maintenance.

Can dry-type transformers be used outdoors?

Yes, with the correct enclosure and protection, they are suitable for outdoor use.

What are the main differences between oil-filled and dry-type transformers?

Dry-type transformers are safer, require less maintenance, and are more eco-friendly, while oil-filled units are generally used for very high-capacity applications.

Are dry-type transformers energy efficient?

Yes, modern designs minimize energy loss and improve overall system efficiency.

Why choose a certified manufacturer?

Certification ensures product safety, compliance with international standards, and long-term reliability.

Request a Quote Now

Our team will get back to you within 24 hours.